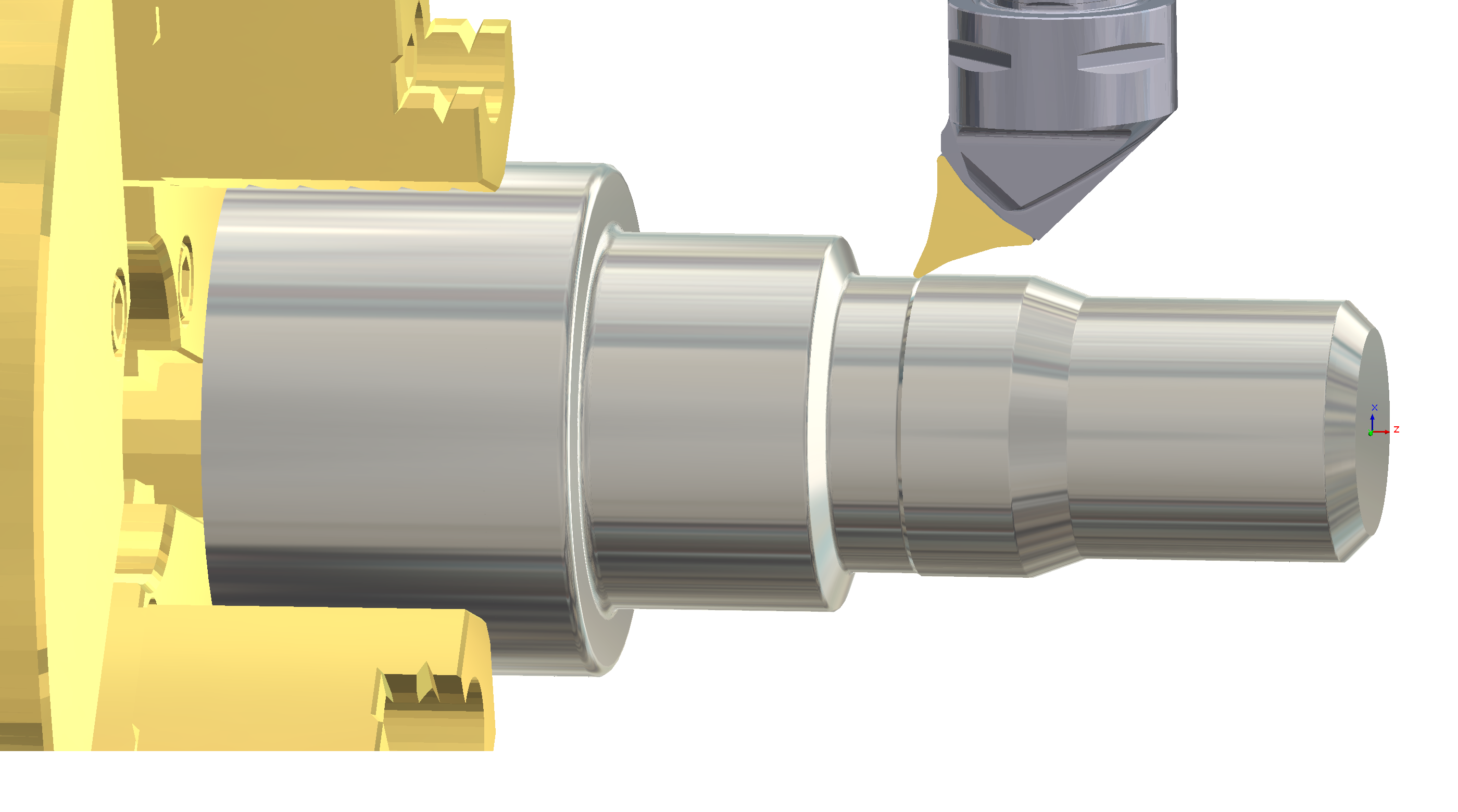

Reduce Part Handling

CAMWorks Mill-Turn provides a solution for both milling and turning on the same machine tool. Allowing for increased productivity and flexibility.

PrimeTurning™ from Sandvik Coromant

- PrimeTurning™ is available in CAMWorks

- Reduce cycle time for turning by 50% or more

- Increase insert tool-life by 500% or more

- Full Library of PrimeTurning™ tools and inserts are included in the TechDB

Probing for Mill-Turn Machines

- Define probing tools with new parameters for probe shank and stylus

- Automatic selection of standard probing cycle based on face/feature selection

- Dynamic display of probing toolpath to avoid collisions and broken probes

- Probe stock and set work offsets automatically

- Support for standard probing cycles

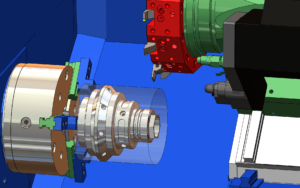

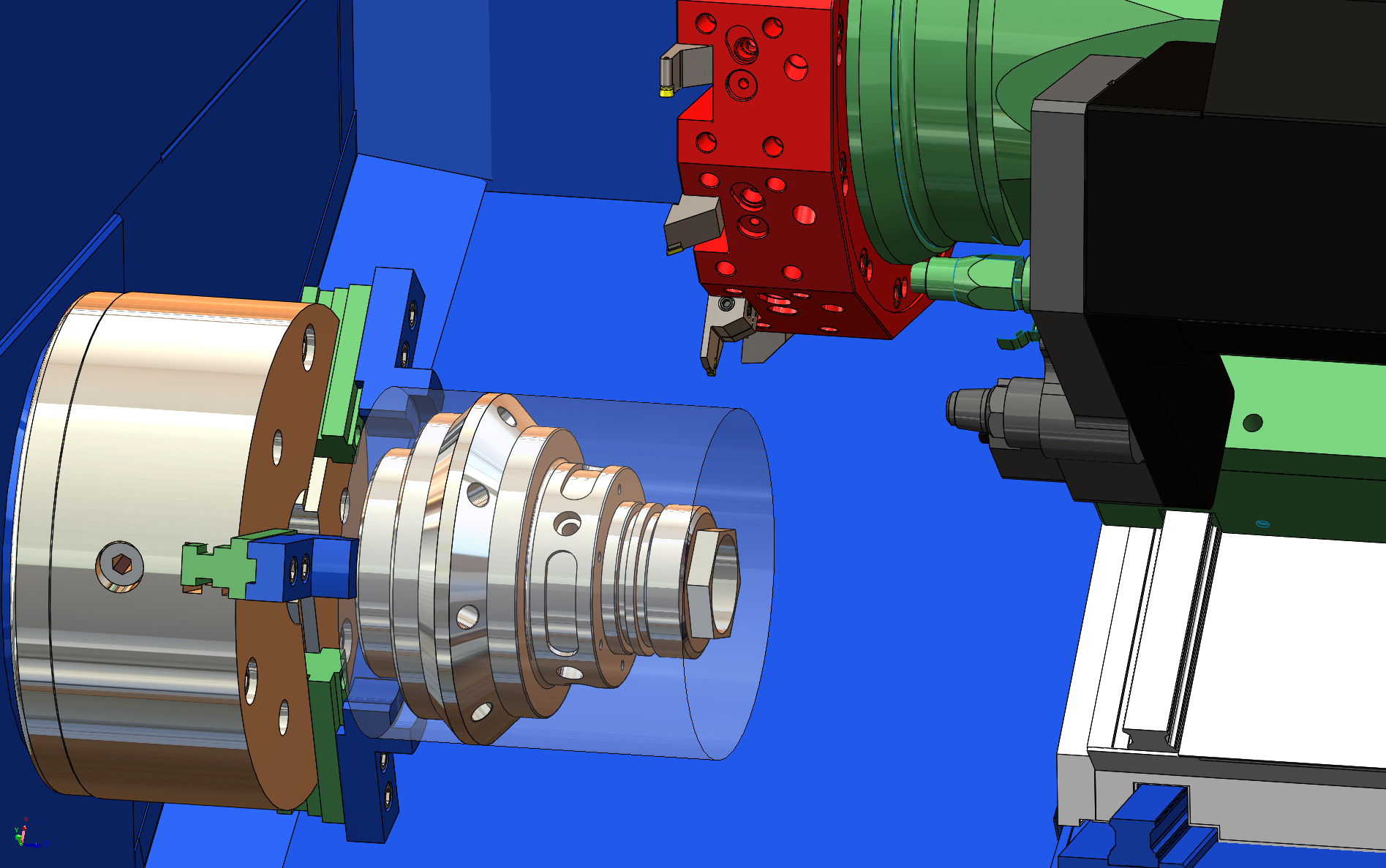

Mill-Turn in SOLIDWORKS Assemblies

- Full Mill-Turn Support in SOLIDWORKS assembly mode

- Include custom chucks, fixtures, and other machine components for simulation and collision checking

- Synchronize simultaneous milling and turning operations with multiple turrets and spindles

- Simultaneously machine both sides of a part or unique parts in the main and sub-spindles

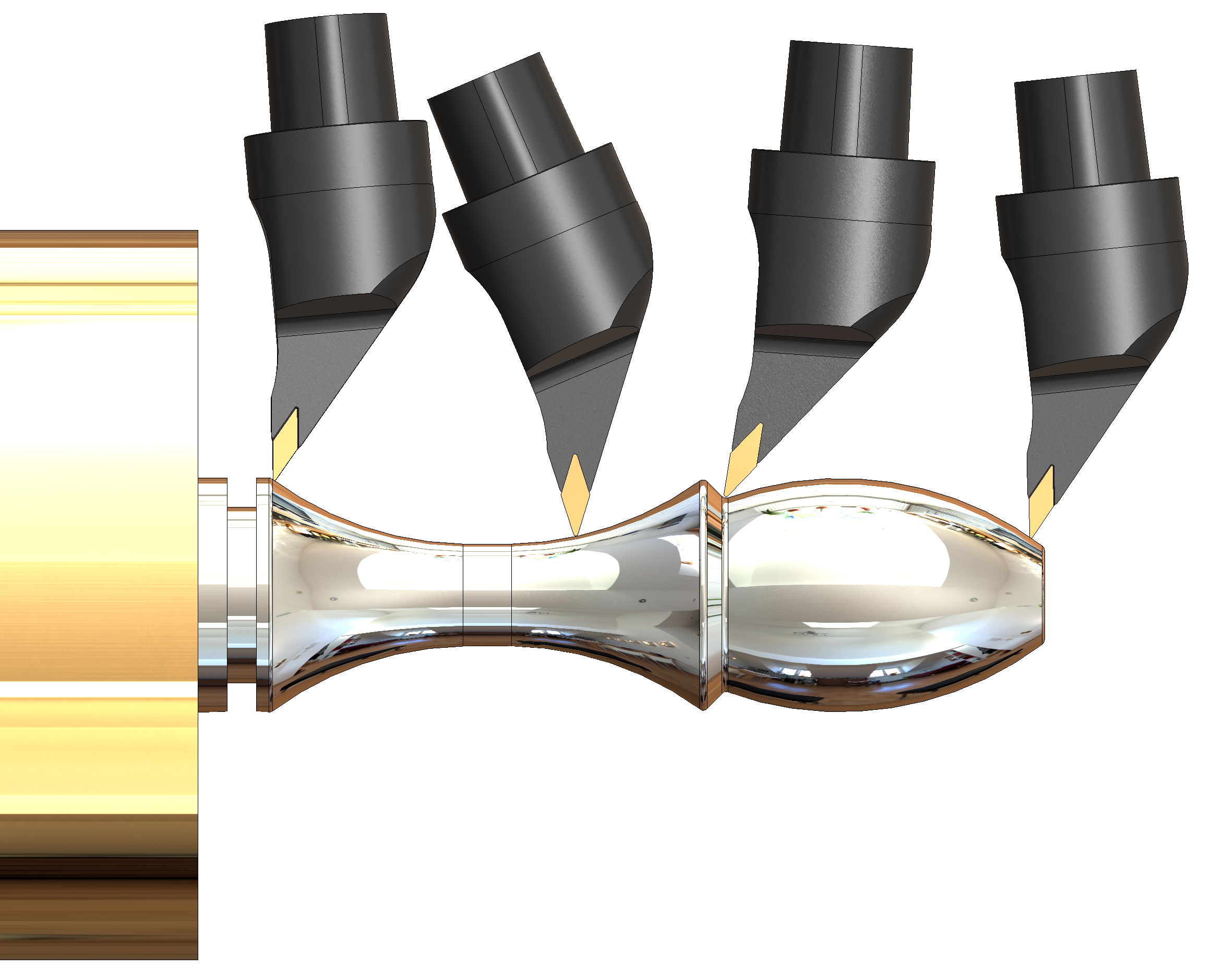

Continuous B Axis Turning

- Reach undercuts using a single finishing tool

- Multiple cutting strategies for flexibility

- User definable limits for the B Axis tilting angle

- Specify effective lead angle or tool normal angle

- Holder clearance setting to avoid collisions

Benefits of Using CAMWorks Mill-Turn

- Reduce Programming Time by 80% or more

- Automate the CNC Programming Process

- Standardize to Improve Quality

- Dramatically Reduce Setup Time

Vietnamese

Vietnamese